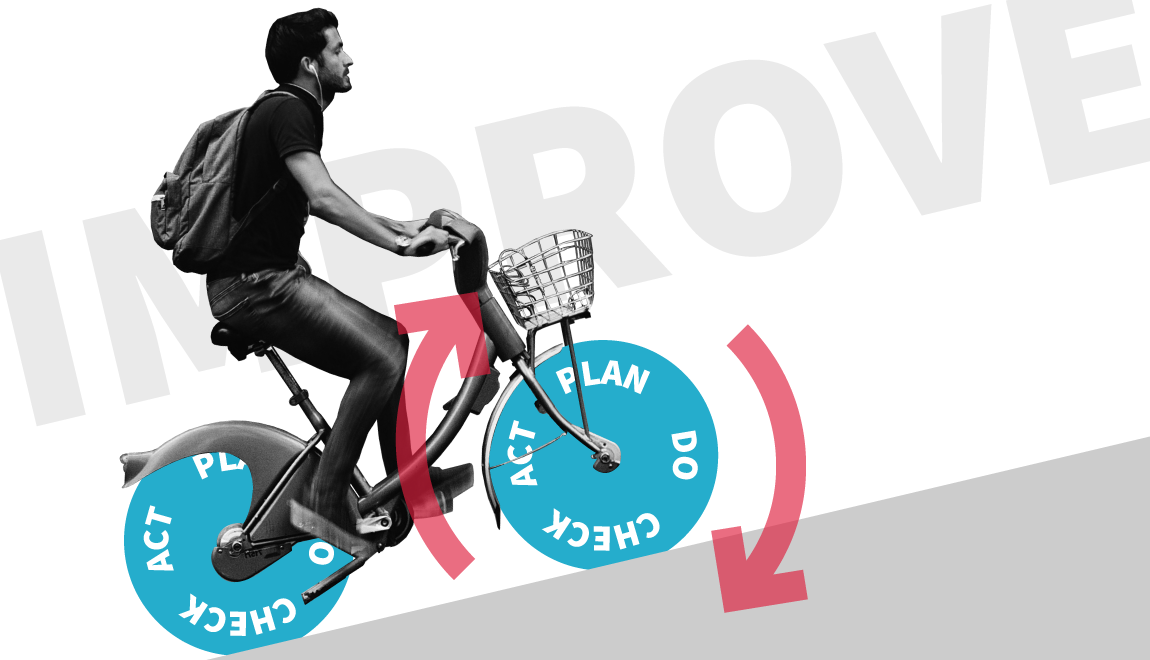

PDCA Cycle - Continuous Improvement for Unstoppable Success

The PDCA cycle, also known as the Deming cycle or Shewhart cycle, is a continuous improvement method in which a process or project is planned, executed, reviewed, and implemented.

The acronym thus stands for Plan, Do, Check and Act and is one of the most popular frameworks in lean organizations.

Using the PDCA cycle, organizations can identify problems, set goals, implement solutions, measure results and make adjustments as needed to achieve continuous improvement. It is a simple but powerful tool to drive improvement and lead to unstoppable success.

Improvements can be made in two ways - as constant, small, incremental improvements over time (also known as Kaizen) or as large, targeted, quantum leap improvements (also known as Kaikaku).

But whether you choose the Kaizen or Kaikaku approach to implementing improvements, it's a good idea to follow the PDCA cycle. In this article, we’ll look how.

In addition, we’ll look how the PDCA cycle can also be used to improve time management in a company.

But no matter if

you decide for the Kaizen or Kaikaku approach when implementing improvements,

it’s recommended to follow the PDCA cycle.

- It’s easy to implement a change; it’s hard to implement a change that works

- PDCA cycle – a simple four step process of improvement

- Plan – take time to think and plan

- Do – implement the plan in order to observe the change

- Check – observe, study, analyze, and reflect

- Act – implement the corrective action and standardize

- Employing PDCA cycle for implementing a time and attendance system

- Employing PDCA cycle for better internal time management

It’s easy to implement a change; it’s hard to implement a change that works

The PDCA cycle is really simple to understand and therefore very easy to implement. But unfortunately, managers rarely apply the recommended basic process of change and improvement. This often leads to not improving at all in two ways:

- doing the same thing over and over again, hoping to achieve a different result;

- impulsively making changes, without being systematic and diligent.

These are also the two biggest pitfalls of change. You should never focus only on the DO part and forget the planning phase before and the analysis phase after. If you do, you may be doing more of the same or not know which change is producing the desired results and which is not.

Following the PDCA cycle helps you deal with stagnation and the uncertainty of an outcome. It helps you move from changes that could lead to even worse results to changes that actually work. The framework also helps you to pivot when a change does not work.

PDCA cycle – a simple four step process of improvement

PDCA cycle has four letters, and thus four phases. First, you plan a change based on your assumptions or hypotheses. Then you do the planned change in a very controlled environment. The next step is to check the results and do the analysis of where the change is leading you.

The last step is to act accordingly or to decide if you’ll keep the change or pivot to something else. When you make this final decision, you have already entered a new cycle of planning and implementing the next change in the queue.

Consequently, the cycle never ends, and you can easily follow the process of continuous improvement. You enter the upward spiral of change.

That’s where the name PDCA cycle comes from; and that’s the process to follow when implementing any change. These are the steps:

- Plan refers to what and why;

- Do refers to performing an experiment and testing;

- Check refers to analysis, reflection and introspection;

- Act refers to implementation and corrective action (pivoting);

Now let’s look every stage of the PDCA cycle a little bit closer.

Plan – take time to think and plan

The first logical step in the PDCA cycle is planning. You have to sit down and think about the final outcome you want to achieve, or the problem you want to solve.

By planning, you can clarify what kind of improvements you want to implement, decide which opportunities to follow, and write down the assumptions (hypotheses or educated guesses) which you want to test.

You also have to analyze and diligently determine what kind of a behavioral change will most likely lead you to the desired result. You need to set measurable and attainable goals (OKRs or KPIs), and you need a strong Why that emotionally empowers you and reminds you of the reason you want to achieve something.

These questions can help you during the planning phase:

- What is the core problem or issue we’re trying to solve?

- Which approaches have we used before?

- What resources do we need and have available for improvement?

- What is the optimal solution we should experiment with?

- What are the main KPIs or key results? How will we measure improvement?

The basic idea of the planning phase is to design a set of controllable experiments where you implement a change on a manageable scale, so you can analyze the possible effects on a greater level. The fact is that only by doing and putting your assumptions to the test and then reflecting on the results are you able to see if your assumptions in the plan are right or wrong.

By doing and reflecting you can decide to validate or reject (confirm or negate) your hypotheses. That leads us to the “do” and “check” phases of the PDCA cycle.

Do – implement the plan in order to observe the change

In the “do” phase, you implement the plan. In a very controlled way, you change your behavior, setup, process, system or whatever will potentially lead to a different, and preferably desired, result. Essentially, the plan meets reality.

When you change your behavior, you interact differently with your environment, and that reshapes the relationships and the direction in which the environment is evolving. Thus, any change causes friction and stress to the established system, and consequently that leads to a polarization of internal and external factors.

Polarization means that every internal or external factor has to become a blocker or a backer of your change. When you act differently, you have supporters of change and forces that want to put things back as they were. And you never know how polarization will happen.

That means your plan mustn’t consider only how the change will affect only your environment as an individual, but also how it will affect the organization as a whole. But only when you do things in real life and you get the first-hand experience (Genchi Genbutsu), can you finally see things as they are in reality and compare them to your plan and assumptions.

The properly executed “do” phase is very easy to spot. If you correctly implement any change, you almost always:

- Start doing something new;

- top doing something old;

- Or both;

Check – observe, study, analyze, and reflect

The next step is to analyze the results. The “check” step is not about auditing, but more about reflecting. That’s why some people prefer to call it the PDSA cycle, where “check” is swapped with “study”.

With reflection (or introspection, as it’s often called) you analyze how the change affected you and your environment after changing your behavior.

In the “check” phase, you analyze which things went well, what didn’t go as planned and expected, and what could have been done differently to get better results. You also brainstorm ideas for the potential next improvements and changes.

In the check phase you need a clear answer to the following questions:

- What went well during the experiment?

- What didn’t go that well?

- How could we do things differently?

- How can we implement a new change?

In scientific terms, you do the evaluation – you compare the results with the plan. You validate or reject your hypotheses. You convert data into information, so you can draw final conclusions and insights and act accordingly. In the “check” phase, you learn how to act based on testing and experimenting. You do validated learning.

The 5 Whys analysis can be a great help when you are performing the “check” phase.

Act – implement the corrective action and standardize

The final step in the PDCA cycle is acting based on the conclusions you obtained from the experiment. It’s about implementing corrective actions based on your plan, the results of the experiment, and reflection insights. There is a decision to be made about the improvement:

- Persevere

- Restore

- Pivot – Change while keeping fundamentals

- Try something completely new

If the change brought the results you wanted, you persevere. The new behavior becomes the new baseline, the new standard way in which you operate. If the change didn’t work as expected and had negative effects, you have two choices: You can either go back to your old behavior (restore), or you can pivot partially or turn to something completely new.

The very important thing to remember when you come to the act phase is that you simultaneously enter the new PDCA cycle and already plan a new improvement and experiment. The PDCA cycle never stops and that’s what leads to constant validated learning and improvements.

Employing PDCA cycle for implementing a time and attendance system

Now let’s look deeper how PDCA cycle can be used in achieving better time management in a company.

In the "Plan" phase, the company would first identify the problems or inefficiencies in the current time and attendance process. These could include problems with employee timeliness, recording hours worked, or calculating overtime. Goals are set for improving the process, such as reducing tardiness or increasing accuracy in timekeeping.

In the next phase, the "Do" phase, the company would implement the planned solutions and improvements. This could include implementing a new time and attendance system, creating a schedule for employees, or conducting training on the new process.

In the "Check" phase, the company would measure and analyze the results of the implementation. This could include collecting data on timeliness, tracking hours worked, or calculating overtime, which would then be compared to the goals established in the planning phase.

Finally, in the "Act" phase, the company would take action based on the results of the analysis. This could include making adjustments to the new process, providing additional training to employees, or continuing to monitor the process to ensure it stays on track.

By applying the PDCA cycle to the process of time tracking and management, companies can continually improve their process and ensure that they are accurately tracking employee time and attendance.

Employing PDCA cycle for better internal time management

If we are trying to be even more innovative, the PDCA cycle can be linked to internal time management. There are four phases in the PDCA cycle and also for important aspects outstanding internal time management.

Planning = Scheduling: Just as you need to plan for change, you also need to plan your workforce for optimal results. It's always about deploying the right number of appropriately skilled people exactly where and when they are needed.

Do = Time & Attendance Tracking: When you start doing something, you also need to start tracking the time and effort spent on new changes. You can only manage and reflect on what you measure.

Check = Time and Attendance Analysis: to check if the change is working, you need to be data-driven. Data from time and attendance management and project time tracking are essential in this regard.

Act = Improve your time investments: The final step is to improve how employees spend their time based on analytics. They should focus their time on projects that require the least effort and produce the best results; and on activities that strengthen the company's competitive advantage.

As with PDCA in general, the process is endless, and thus even time management improvements can be endless. It's like a Flywheel that spins faster and faster and becomes more and more persistent.

You start with small changes, such as in time management, which lead to bigger and bigger changes until you become unstoppable. This is the true power of the PDCA cycle.